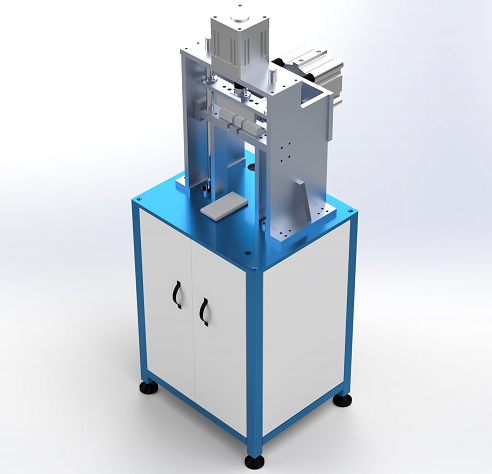

Tube Preparation: A straight, hollow metal tube is chosen based on the desired size and material properties. The end of the tube might be prepped for cleaning or chamfering (slightly beveling the edge).

Positioning: The tube is inserted and secured in the machine's holding device.

Flared Profile Selection: Depending on the application, the desired flare profile is chosen. Common flare types include:

Cone Flare: A simple cone-shaped expansion for general-purpose connections.

Double Flare: A two-step flare with an inward flange at the end, used for high-pressure applications.

Bead Flare: A rolled-over lip at the end of the tube, often used for soft metal tubing.

Flaring Action: Using a cone-shaped tool or die, the machine applies controlled pressure to the tube end. This pressure forces the metal to expand and conform to the selected flare profile.

Completion: Once the desired flare shape is achieved, the pressure is released, and the finished flared tube is removed.

Benefits of Tube Flaring:

Leak-Proof Connections:

The flared profile creates a tight seal against a matching fitting, preventing leaks in fluid or gas lines

Strong Connection:

The flaring process strengthens the tube end, improving its resistance to pulling forces.

Versatility:

The machine can accommodate various tube sizes and materials, offering flexibility for different applications.

Efficient Process:

Tube flaring machines provide a fast and reliable method for creating secure connections.

Tube flaring machines are widely used in industries that rely on leak-proof and secure connections for fluids and gases. Some common applications include:

⦁ Plumbing:

Connecting pipes for water, gas, and refrigeration systems.

⦁ HVAC Systems:

Joining tubes in air conditioning and heating equipment.

⦁ Automotive Industry:

Creating connections in fuel lines, brake lines, and hydraulic systems.

⦁ Medical Equipment:

Flaring tubing for instruments and medical gas lines.

By using a tube flaring machine, technicians can ensure strong and reliable connections in various systems, contributing to their overall safety and functionality.